M. Cowen, J.M. Powers

See the updated 500 cycle testing results here.

INTRODUCTION

A dry heat sterilizer that shortens sterilization cycles times to under 20 minutes while reducing corrosion by removing steam sterilization is a significant advance for reprocessing dental instruments. As the sterilization temperatures of 375⁰F (191 ⁰C) could decompose some hydrocarbon-based oil lubricants specific to handpiece reprocessing, the need of alternative lubricant systems that can sustain operating and sterilization temperatures up to 400 ⁰F may be needed. In the first phase of our validation of this RH-Pro11 HVHA (High-Velocity Hot Air) sterilization system, we measured the performance of new and used handpieces before and after 250 sterilization cycles to validate the compatibility of the sterilizer and handpiece functionality. We used the handpiece manufacturer’s lubricants every 10 cycles to see if there was any incompatibility of the lubricant with the sterilizer as well. The used Midwest handpieces had been previously reprocessed with hydrocarbon-based lubricants for an unknown number of cycles; however, the initial performance was within manufacturer specified levels. Handpieces that showed a deterioration of performance were then cleaned and lubricated with a new synthetic food-grade fluorinated hightemperature cleaning and lubricant system SteriKleen™ and SteriLUBE™.

CONCLUSION

The Bien Air electric CA 1:5 handpiece, air-driven Tornado X LK, and Midwest Phoenix showed no performance decrease after 250 sterilization cycles with the RH-Pro11 HVHA sterilizer. A used handpiece that previously was reprocessed with incompatible lubrication systems could be sterilized for 250 cycles and returned to original performance specifications with the SteriKleen™ and SteriLUBE™ systems.

EXPERIMENTAL DESIGN

Equipment: DENTAL ADVISOR Handpiece Torque Test Platform and Instron 5866 universal test machine

Handpieces: New Bien Air Handpieces, CA 1:5 electric handpiece [SN:19F0014] tested with KaVo ELECTROtorque Plus motor, and Tornado X LK [SN:19B0068] @ 46 psi, Used Dentsply Midwest Handpieces, Phoenix [SN:2187] and Tradition Pro [SN:4299] @43 psi.

Tests: Noise (dB), Speed (RPM), Stall Torque(N-cm), Power (W)

METHODS

Performance Testing: The handpiece was attached to the test platform in a handpiece holding assembly. A spindle with a brake sphere was inserted into the chuck of the handpiece and the holding assembly adjusted so that the spindle was aligned with the torque sensor. The speed of the spindle was measured with a Monarch Infrared speed sensor and ACT 3 Electronic Tachometer. The torque sensor was connected to the load cell of the Instron 5866 system on which the test platform was mounted. During the testing, the handpiece was pressed downward along the axis of the spindle shaft with varying loads so that the brake sphere was pushed against the brake, which was attached to the torque sensor. The friction of the brake sphere against the brake produced a torque, which was registered by the load cell as a force while the speed was measured. Several torque versus speed points were taken to define the torque versus speed curve for each handpiece and used to calculate power in Watts. The stall torque was determined as the torque produced at the point during loading when the rotation of the spindle running at maximum speed was braked to zero RPM. The noise level was measured according to ISO 14457 methods by measuring the A-weighted sound pressure 0.45 meters from the handpiece with a type 1 precision sound level meter (DSM403SD, General Tools & Instruments).

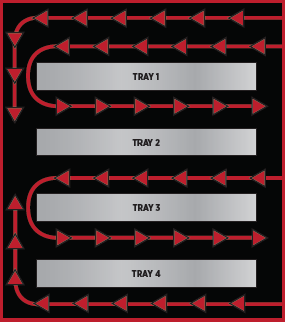

Sterilization: Handpieces were subjected to 250 sterilization cycles unwrapped using the RH-Pro11 HVHA system with 10-minute cycles under the “handpiece” setting. Every 10 cycles, the handpieces were removed, lubricated according to manufacturer instructions using Lubrifluid (Bien Air) or Midwest Plus Spray, and operated for at least 60 seconds before the next 10 sterilization cycles.

RESULTS

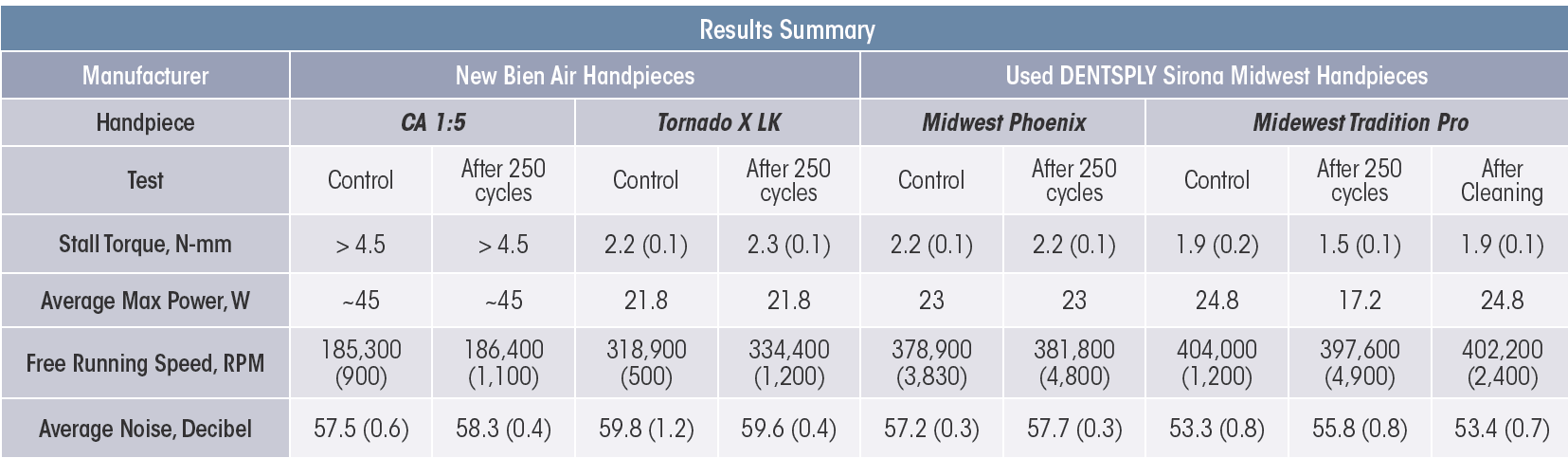

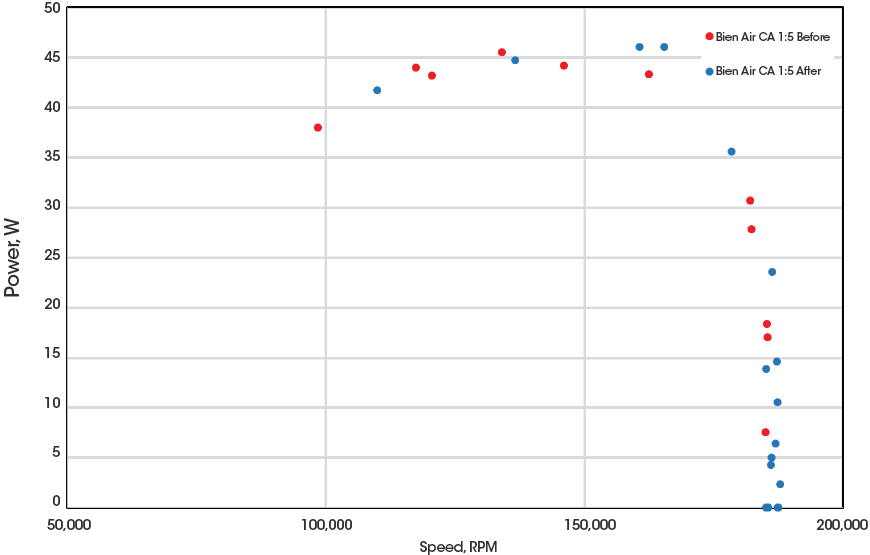

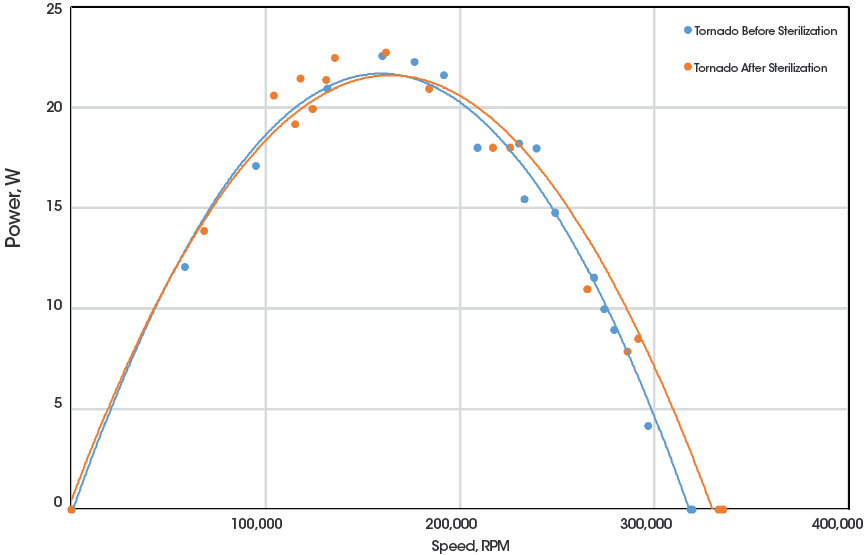

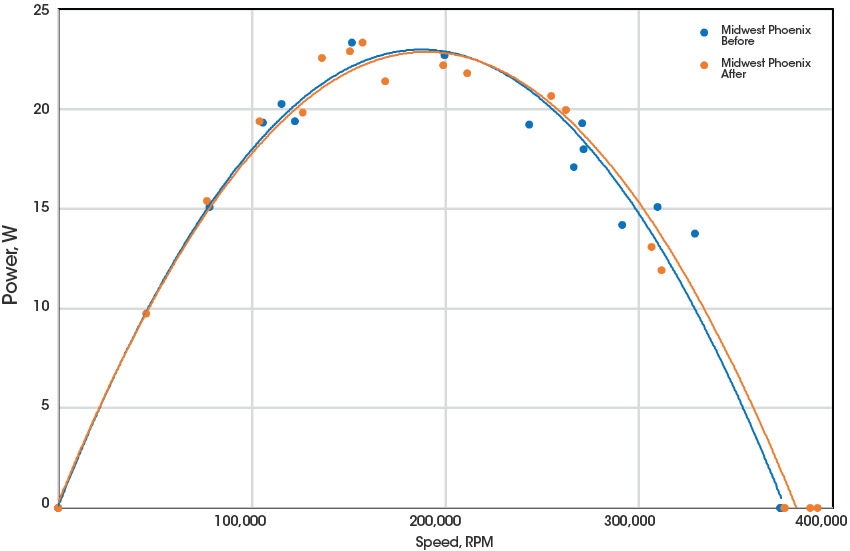

There were no detectable differences in performance of noise generation, speed, stall torque or power output after 250 reprocessing cycles with the RH-Pro11 HVHA sterilizer for the two new Bien Air handpieces and the used Midwest Phoenix handpiece. As can be seen on the plot of the handpiece power measurements, the average performance measurements lie along the same curve with identical peak power. A stall torque for the electric handpiece could not be definitely measured because, after the handpiece stalls, it generates a rapid oscillating force curve ranging from 3.5 to over 6 N-mm of torque. The noise level difference before and after reprocessing was less than a decibel difference for both handpieces and considered equivalent as small ambient noise changes may account for such a small difference. No visual differences were noted on any handpiece after the 250 sterilization cycles, though the used handpieces showed signs of corrosion around the spray ports prior to initial testing and remained unchanged.

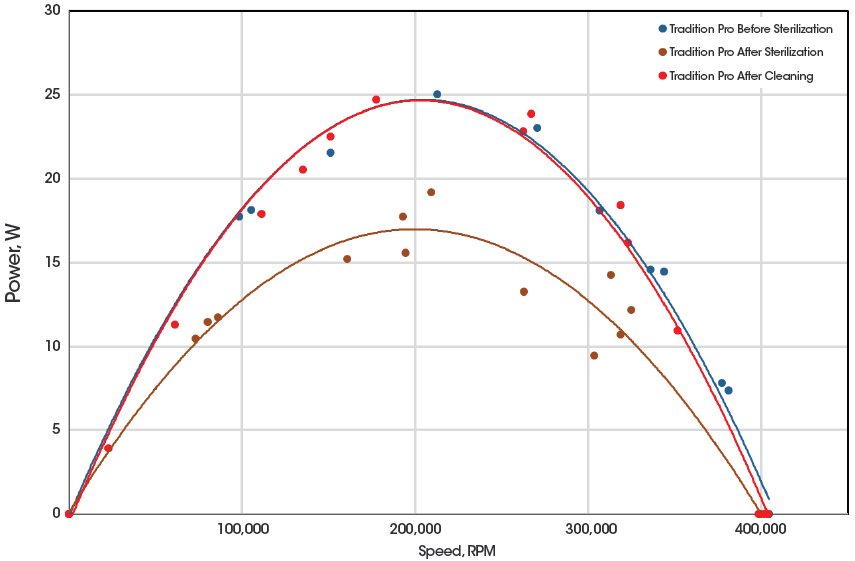

The Midwest Tradition Pro handpiece did show a decrease in power and noise generation. To test if this is a result of degradation of lubricant, the handpiece was thoroughly cleaned using a synthetic Fluorinated cleaner and lubricant system (SteriKleen™ and SteriLUBE™ ) and discolored runoff was visibly expelled. The performance of the handpiece after additional cleaning returned to pre-sterilization levels indicating successful cleaning of the handpiece. Follow up testing of this cleaning and lubrication system may show its effectiveness to prepare a variety of used handpieces for this sterilization system or improve the performance of dirty handpieces to original specifications.

Figure 1: Bien Air CA 1:5 Power Curve

Figure 2: Bien Air Tornado Power Curve

Figure 3: Midwest Phoenix Power Curve

Figures 1-3: The new Bien Air handpieces and used Midwest Phoenix handpiece showed no decrease in performance after 250 sterilization cycles with the RH-Pro11 HVHA.

Figure 4: Midwest Tradition Power Curve

Figure 4: The used Midwest Tradition Pro handpiece did show some decrease in performance and increased noise when lubricated with the hydrocarbon-based Midwest Plus after 250 cycles. The performance was able to be returned to baseline levels after cleaning and lubrication with the SteriKleen™ and SteriLUBE™ systems.