The Recognized Gold Standard in Thermal Sterilization

This technology evolved from NASA’s early research to discover the best efficacious and non-destructive decontamination technology for spacecraft.

RapidHeat offers healthcare providers a faster, waterless, chemical free, low maintenance alternative in the sterile processing of medical and dental instruments.

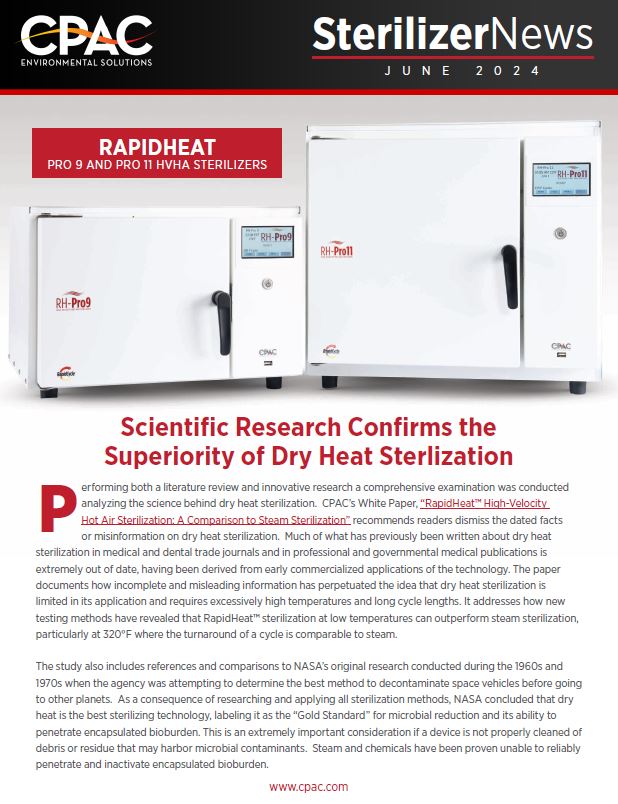

RapidHeat sterilization technology utilizes an advanced proprietary form of circulating “High-Velocity Hot Air” (HVHA) in a sealed chamber at the rate of 200-300 air exchanges per minute. Due to the uniform distribution of HVHA, a RapidHeat sterilizer can process wrapped or unwrapped medical and dental instrumentation with greater

efficiency in as little as 14-21 minutes total processing time to achieve a 12-Log spore kill. To accommodate the processing of temperature-sensitive items, RapidHeat sterilization technology has been recently advanced to incorporate “Low-Temperature” sterilization cycles with processing times equivalent to steam sterilizers.